Description

Product Description

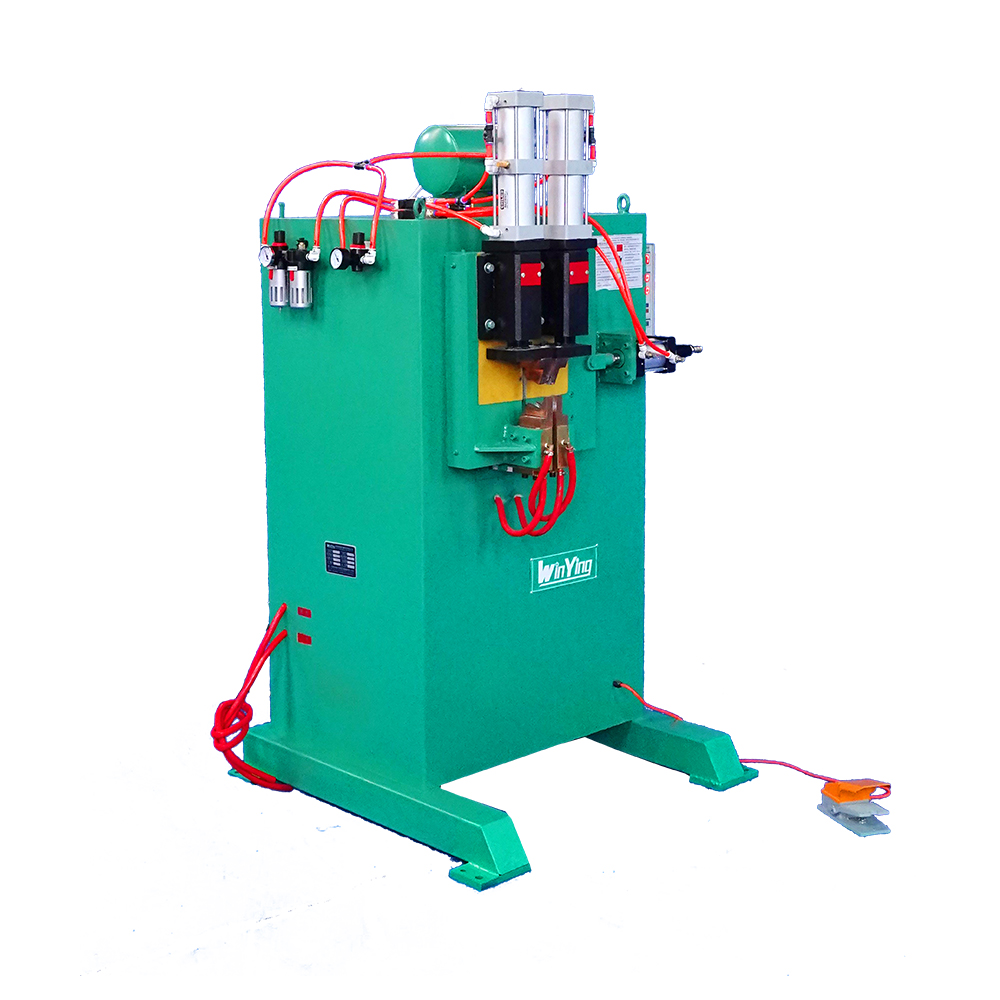

The butt workpiece is automatically clamped, and then controlled by gas and liquid, the end face of the welded workpiece is thermoplasticized after being powered slowly to remove the oxidation and flash of the bumps on the surface of the welded workpiece. The welding area becomes hotter and hotter, and the butt welding speed is accelerated. The flash and splash make the two contact surfaces completely welded together, and finally the two end faces are pressed together under rapid pressure and overforging. Cut off the current and weld complete. The welding strength is high, the compactness is good, no false welding, no slag inclusion, no porosity.

Performance Feature

The equipment is driven by full air pressure, the key components are made of well-known domestic brands, the working pressure is stable and the response is fast; Welding parameters, pressure specifications are all set by the man-machine interface and can be saved; air pressure station pressure, temperature, liquid level and welding current, welding distance comprehensive real-time monitoring, abnormal alarm automatic stop protection and prompt; welding mold quick change, wear-resistant design, and with flange positioning function, improve work efficiency; three-phase frequency conversion technology, power factor more than 98%, no need to compensate the grid, saving energy; After adjusting the welding voltage, air pressure and hydraulic pressure, you can put the welded part into the clamp mouth, and press the start button (or press the foot switch) to complete the welding process automatically.

Machine Parameters

| Model | No-load Voltage | Maximum Current | Water Flow | Welding Thickness | Overall Dimensions |

| WY-JM-63 | 9.8V | 31000A | 10L/min | 4mm+4mm | 1000x1000x1800mm |