Description

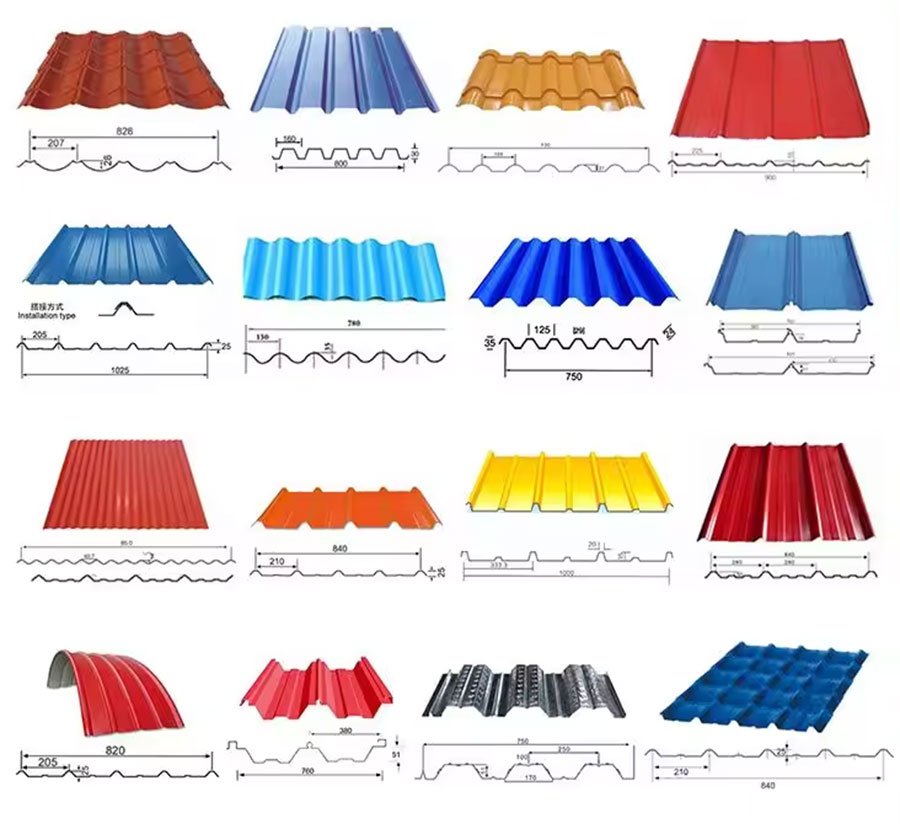

The Roll Forming Machine is composed of feeding, forming, and post-forming cutting. The plate produced has a flat and beautiful appearance, high strength, and durability. It is widely used in industrial and civil buildings, such as factories, warehouses, gymnasiums, exhibition halls, theaters, etc. House surfaces and walls.

|

Decolier

|

Loading capacity

|

1.5 tons

|

|

Quantity

|

1 sets

|

|

|

Type

|

Manual

|

|

|

Main forming part

|

Thickness

|

0.3-0.8mm

|

|

Material

|

GI/ PPGI

|

|

|

Roller station

|

22

|

|

|

Roller material

|

GCR12 with tempering and grinding , heat treatment hardness HRC58-62, galvanized coating 0.05mm

|

|

|

Shaft diameter

|

85mm

|

|

|

Shaft material

|

Solid 45# steel with tempering and hardening

|

|

|

Speed

|

15m/min

|

|

|

Power

|

7.5KW

|

|

|

Motor

|

Shanghai Lichao/Guomao (China famous brand)

|

|

|

Drive mode

|

By 1 inch chain

|

|

|

voltage

|

As request

|

|

|

Machine frame

|

25mm mild steel

|

|

|

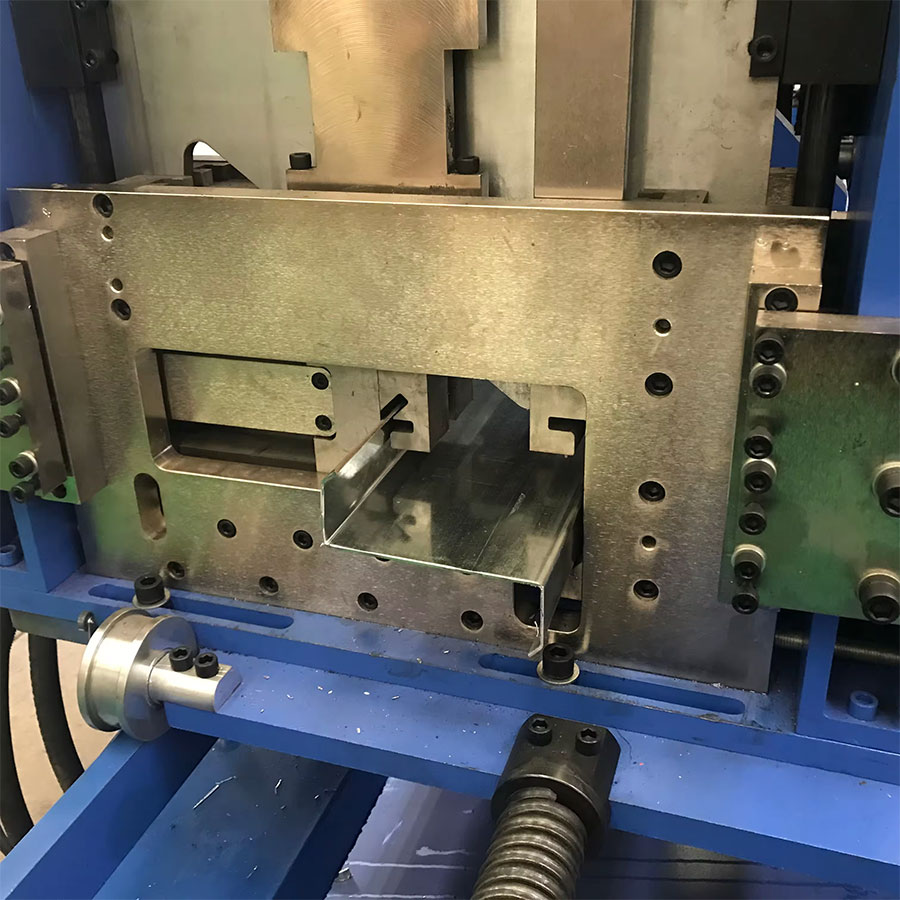

Shearing way

|

Hydraulic method

|

|

|

Blade material

|

CR Mov 12 with tempering 58-60HRC

|

|

|

Transmission

|

Chain

|

|

|

control system

|

Screen brand

|

Delta (made in Taiwan)

|

|

Frequency converter

|

Delta (made in Taiwan)

|

|

|

Main electric apparatus

|

Schneider (Franch Brand)

|

|

|

Encoder

|

Omorn (Japanese brand)

|

|

|

Langue

|

English (as request)

|

|

|

Function

|

To control speed, cutting length ,batch quantity

|

|

|

Hydraulic station

|

4.5kw

|

|

|

Run-out table

|

Length

|

1.5m (as request)

|

|

Material

|

1-1.5mm C stud

|

|

|

Loading capacity

|

1.5 tons

|

Whole in one piece to save space and shipment cost.