Description

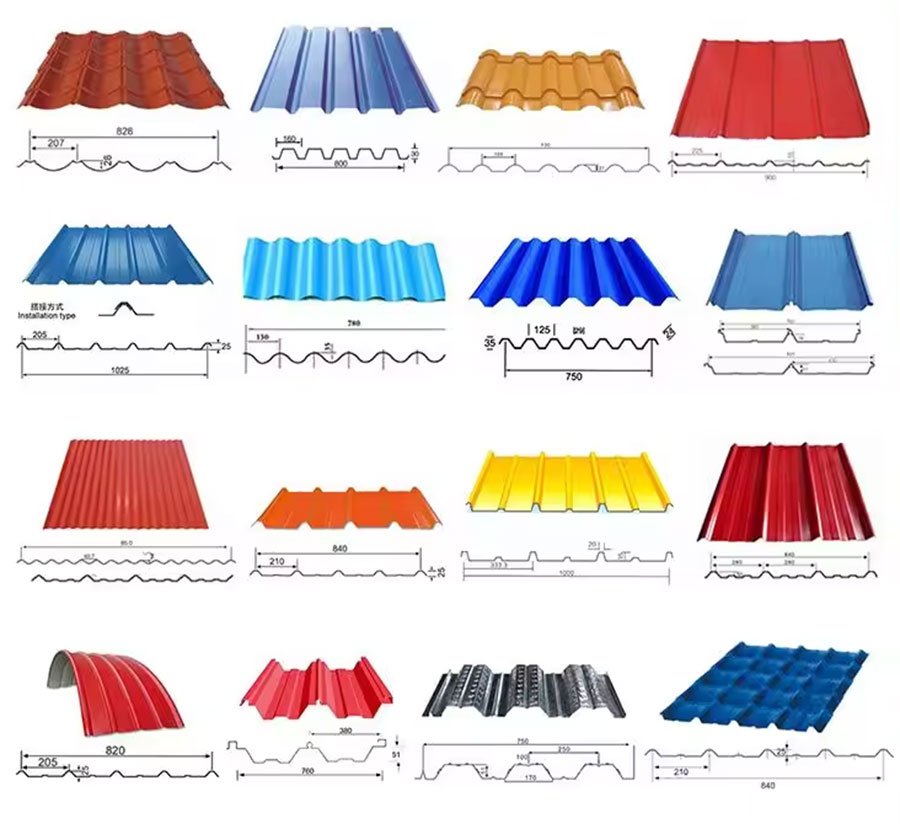

The corrugated roof sheet making production line can finished products of metal roof tile.

They have many features,such as high precision,accurate shape and size,large wave height and good adhesiveness.

Otherwise,the production can be overlap well .In the steek structure house,it can shield from the rain,insulation and cold insulation.

The corrugated roof sheet roll forming machine main designed by the profile drawings.

Technical parameters of corrugated steel plate rolling machine:

1. Machine frame: Middle plate with H shape steel beam

2. Material thickness: 0.35-0.6mm

3. Material of forming mold: Cr12 quenched steel

4. Hydraulic oil pump press: 32Mpa

5. Voltage: 415 v 50hz 3phase or customize

6. Feeding equipment

1) Motor power: 3kw

2) Chain transmission

3) DC motor: calculates arc length automatically

7. Hydraulic system

1) Advanced hydraulic system

2) Power: 5.5kw

8. Automatic control system

1) Screen: 5.7 inch DELTA screen from Taiwan

2) PLC: DELTA from Taiwan

Whole in one piece to save space and shipment cost.